Modular Stands: Installation Issues and How to Avoid Them

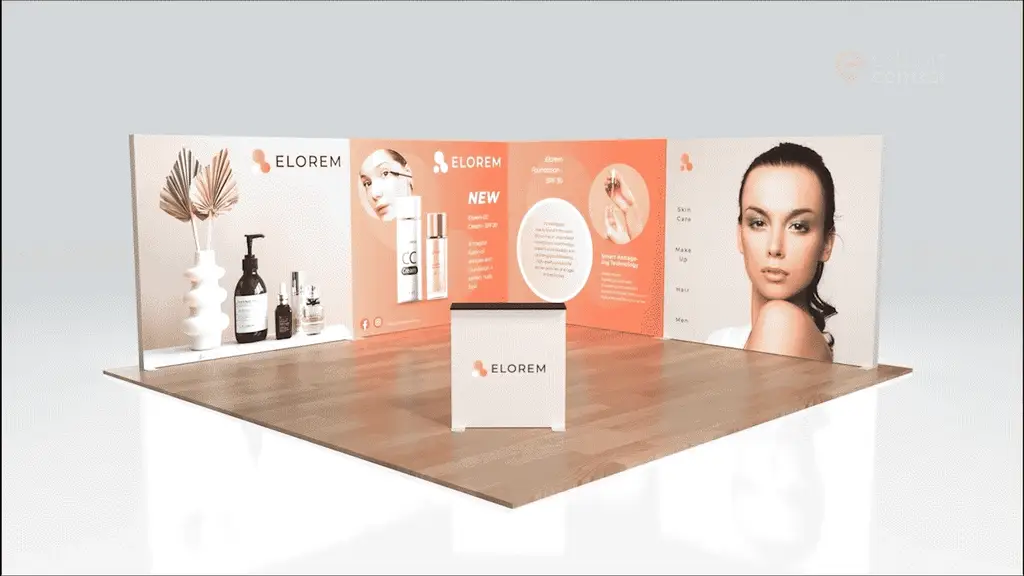

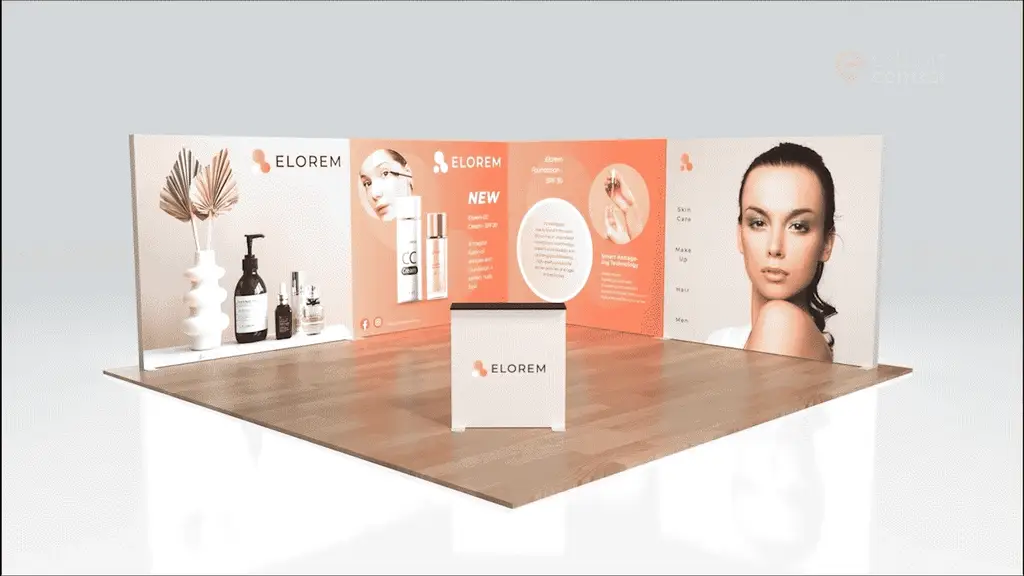

In the world of exhibitions and trade shows, modular stands have gained immense popularity due to their versatility and convenience. Modular stands are types of exhibition stands that are designed using individual interchangeable components, allowing exhibitors to create unique and customizable booth designs, without the intricacies found in installing custom exhibition stands. These stands are often constructed from lightweight, easily transportable materials, making them a preferred choice for exhibitors seeking flexibility and cost-effectiveness.

Unlike custom exhibition stands, modular systems are faster and uncomplicated to install, best for exhibitors who are always mobile. Custom modular stands can also be equally attractive and interesting to see.

2. Incorrect Component Ordering

Purchasing modular stand components from different suppliers can sometimes result in discrepancies between the ordered parts. Mismatched pieces may not fit together properly, leading to frustration and wasted time during the installation process. To avoid this issue, it’s crucial to double-check orders and ensure all components are compatible before starting the assembly of all types of exhibition stands.

Also read: Lumi SEG Light Box: Step-By-Step Installation Guide

3. Lack of Experience

Exhibition stands can be challenging to construct, especially for first-time exhibitors or those without experience in handling modular stands. Inexperience may lead to improper assembly, compromising the stand’s stability and overall appearance. It is advisable for exhibitors to seek guidance from experienced stand builders or consult the supplier’s support team to ensure a smooth installation process.

4. Inadequate Tools and Equipment

Having the right tools and equipment is essential for the successful installation of modular stands. Insufficient or improper tools may result in damage to the stand components or cause delays in the setup. Exhibitors should invest in the necessary tools and ensure they are in good condition before starting the installation.

5. Poor Choice of Exhibition Stand Materials

Selecting the right materials for the modular stand is crucial to its overall durability and stability. Some exhibitors may opt for cheaper materials to save costs, but this can lead to compromises on quality and longevity. Choosing sturdy and reliable materials is vital to ensure the stand can withstand the rigors of the exhibition and remain in good condition throughout the event.

2. Incorrect Component Ordering

Purchasing modular stand components from different suppliers can sometimes result in discrepancies between the ordered parts. Mismatched pieces may not fit together properly, leading to frustration and wasted time during the installation process. To avoid this issue, it’s crucial to double-check orders and ensure all components are compatible before starting the assembly of all types of exhibition stands.

Also read: Lumi SEG Light Box: Step-By-Step Installation Guide

3. Lack of Experience

Exhibition stands can be challenging to construct, especially for first-time exhibitors or those without experience in handling modular stands. Inexperience may lead to improper assembly, compromising the stand’s stability and overall appearance. It is advisable for exhibitors to seek guidance from experienced stand builders or consult the supplier’s support team to ensure a smooth installation process.

4. Inadequate Tools and Equipment

Having the right tools and equipment is essential for the successful installation of modular stands. Insufficient or improper tools may result in damage to the stand components or cause delays in the setup. Exhibitors should invest in the necessary tools and ensure they are in good condition before starting the installation.

5. Poor Choice of Exhibition Stand Materials

Selecting the right materials for the modular stand is crucial to its overall durability and stability. Some exhibitors may opt for cheaper materials to save costs, but this can lead to compromises on quality and longevity. Choosing sturdy and reliable materials is vital to ensure the stand can withstand the rigors of the exhibition and remain in good condition throughout the event.

Don’ts:

Don’ts:

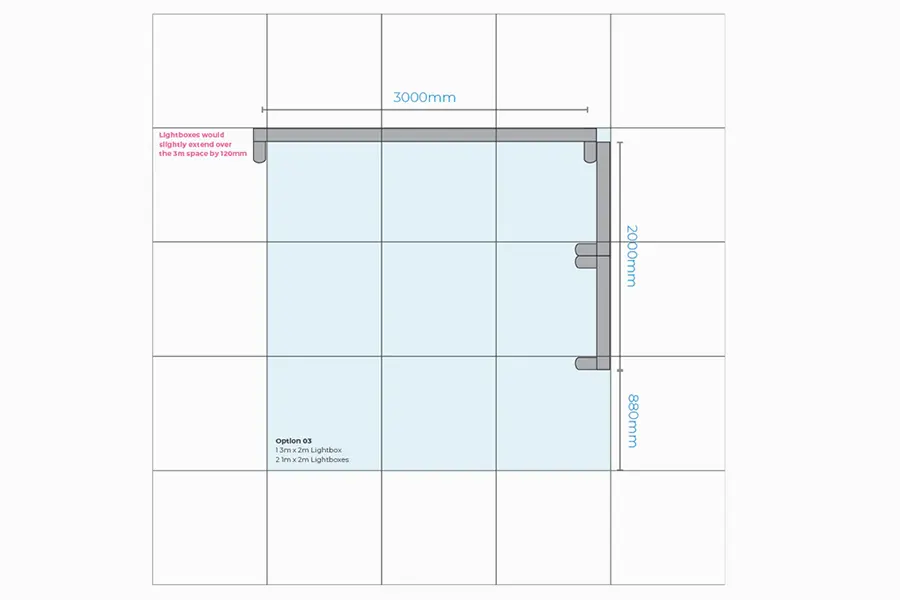

One of the best items that you can use among the many modular solutions is the LUMI lightbox, an ideal addition to your exhibition stand design. It is cost effective because it can be disassembled, no tools required to assembling it , and very attractive to use in a trade show.

One of the best items that you can use among the many modular solutions is the LUMI lightbox, an ideal addition to your exhibition stand design. It is cost effective because it can be disassembled, no tools required to assembling it , and very attractive to use in a trade show.

What is a Modular Stand?

Modular stands for exhibitions have become a game-changer for businesses of all sizes. Whether it’s a small startup or a multinational corporation, these modular systems offer an ideal solution to showcase products and services in an engaging and attractive manner.Common Problems When Installing Modular Stands

While modular stands offer several benefits, they also come with their share of installation challenges. Below are some common modular stand problems exhibitors may encounter when assembling modular stands: 1. Complexity of Assembly The modularity that makes these exhibition stands so appealing can also lead to complexity during the assembly process. Assembling various components and ensuring they fit together seamlessly requires careful planning and attention to detail. Failure to understand the assembly instructions can lead to misalignments, instability, and, in some cases, structural failures. It can be daunting at first but once you’ve tried installing your modular stand, it gets a lot easier. You can then experiment with the different creative ways to assemble your modular stand. 2. Incorrect Component Ordering

Purchasing modular stand components from different suppliers can sometimes result in discrepancies between the ordered parts. Mismatched pieces may not fit together properly, leading to frustration and wasted time during the installation process. To avoid this issue, it’s crucial to double-check orders and ensure all components are compatible before starting the assembly of all types of exhibition stands.

Also read: Lumi SEG Light Box: Step-By-Step Installation Guide

3. Lack of Experience

Exhibition stands can be challenging to construct, especially for first-time exhibitors or those without experience in handling modular stands. Inexperience may lead to improper assembly, compromising the stand’s stability and overall appearance. It is advisable for exhibitors to seek guidance from experienced stand builders or consult the supplier’s support team to ensure a smooth installation process.

4. Inadequate Tools and Equipment

Having the right tools and equipment is essential for the successful installation of modular stands. Insufficient or improper tools may result in damage to the stand components or cause delays in the setup. Exhibitors should invest in the necessary tools and ensure they are in good condition before starting the installation.

5. Poor Choice of Exhibition Stand Materials

Selecting the right materials for the modular stand is crucial to its overall durability and stability. Some exhibitors may opt for cheaper materials to save costs, but this can lead to compromises on quality and longevity. Choosing sturdy and reliable materials is vital to ensure the stand can withstand the rigors of the exhibition and remain in good condition throughout the event.

2. Incorrect Component Ordering

Purchasing modular stand components from different suppliers can sometimes result in discrepancies between the ordered parts. Mismatched pieces may not fit together properly, leading to frustration and wasted time during the installation process. To avoid this issue, it’s crucial to double-check orders and ensure all components are compatible before starting the assembly of all types of exhibition stands.

Also read: Lumi SEG Light Box: Step-By-Step Installation Guide

3. Lack of Experience

Exhibition stands can be challenging to construct, especially for first-time exhibitors or those without experience in handling modular stands. Inexperience may lead to improper assembly, compromising the stand’s stability and overall appearance. It is advisable for exhibitors to seek guidance from experienced stand builders or consult the supplier’s support team to ensure a smooth installation process.

4. Inadequate Tools and Equipment

Having the right tools and equipment is essential for the successful installation of modular stands. Insufficient or improper tools may result in damage to the stand components or cause delays in the setup. Exhibitors should invest in the necessary tools and ensure they are in good condition before starting the installation.

5. Poor Choice of Exhibition Stand Materials

Selecting the right materials for the modular stand is crucial to its overall durability and stability. Some exhibitors may opt for cheaper materials to save costs, but this can lead to compromises on quality and longevity. Choosing sturdy and reliable materials is vital to ensure the stand can withstand the rigors of the exhibition and remain in good condition throughout the event.

Modular Stand Do’s and Don’ts

To overcome the challenges associated with modular stand installation, consider the following do’s and don’ts: Do’s:- Plan Ahead: Proper planning is essential before beginning the installation process. Create a detailed layout of the stand, mark all the components, and ensure you have all the necessary tools and materials.

- Follow Instructions: Carefully read and follow the assembly instructions provided by the supplier. These instructions are crucial for correct installation and maintaining the stand’s integrity.

- Seek Professional Help: If you lack experience in assembling modular stands, consider hiring professional stand builders or consult with the supplier’s support team. Their expertise can save you time, effort, and potential headaches.

- Inspect Components: Before starting the assembly, inspect all components for any damage or manufacturing defects. Notify the supplier immediately if you notice any issues to get replacements in time.

- Secure Electrical Connections: If your modular stand includes electrical components, ensure that all connections are secure and meet safety standards. Faulty wiring can pose a significant safety hazard.

Don’ts:

Don’ts:

- Rush the Assembly: Take your time during the installation process to avoid making mistakes. Rushing can lead to errors that might compromise the stability and safety of the stand.

- Overlook Safety Measures: Always prioritise safety. Avoid taking shortcuts or ignoring safety guidelines provided by the supplier.

- Disregard Weight Limits: Modular stands have weight limits for components, especially if they include shelves or displays. Overloading these components can lead to collapses or instability.

- Neglect Post-Installation Inspections: After assembling the stand, inspect it thoroughly for any loose connections or structural issues. Address these problems immediately to prevent accidents during the event.

- Forget to Prepare for Dismantling: Plan ahead for the dismantling process. Properly label and store components to make the process easier for future exhibitions.

Safety Precautions When Assembling Modular Stands

Safety should always be the top priority when installing modular stands. Here are some essential safety precautions to follow:- Protective Gear: Wear appropriate protective gear, such as gloves and safety goggles, when handling stand components and tools.

- Stable Foundation: Ensure that the exhibition floor can support the weight of the modular stand. Use stabilisers or anchoring systems if necessary.

- Secure Components: Properly fasten all components together using the recommended methods and tools. Check for loose connections regularly.

- Electrical Safety: If the stand includes electrical components, ensure that all electrical connections are made securely and professionally to prevent hazards like electric shocks or short circuits.

- Fire Safety: Be mindful of fire safety regulations when using lighting, electrical appliances, or flammable materials in the stand design.

- Emergency Exits: Keep emergency exits and walkways clear to ensure smooth evacuation in case of any unforeseen circumstances.

One of the best items that you can use among the many modular solutions is the LUMI lightbox, an ideal addition to your exhibition stand design. It is cost effective because it can be disassembled, no tools required to assembling it , and very attractive to use in a trade show.

One of the best items that you can use among the many modular solutions is the LUMI lightbox, an ideal addition to your exhibition stand design. It is cost effective because it can be disassembled, no tools required to assembling it , and very attractive to use in a trade show.

Share

Facebook

Twitter

Pinterest

LinkedIn

Author

Geim Bernard Eran

Geim, a seasoned Product Manager at Exhibit Central, efficiently manages product orders, stock count, and research and development initiatives, demonstrating a sharp focus on market trends and dedication to excellence. He enhances customer experiences through product training, creating compelling marketing materials, and user-friendly instruction manuals, all while ensuring efficient product management and development.

Latest posts

Retail Signage: The Silent Salesperson Boosting Your Business

Retail signage is the unsung hero of the retail world. It’s the silent salesperson that greets customers, informs them about …

Display Counters for Retail Stores: Attract Customers and Boost Sales

Display retail counters are the workhorses of retail stores, playing a crucial role in showcasing products, facilitating sales, and enhancing …

Expo Marketing: A Comprehensive Guide to Maximise Your ROI

Expo marketing, also known as trade show marketing or exhibition marketing, is a powerful strategy for businesses to connect with …

Design Your Dream Exhibition: A Step-by-Step Guide to Exhibition Space Design Plans

Imagine your ideal exhibition experience. Visitors flock to your space, eyes wide with curiosity. They’re not just passively browsing; they’re …